Especially when dealing with new suppliers it is not uncommon that the first few devices need a little extra love. For those cases a workshop comes in handy. #newspace #lifelessonslearned #berlinstartups

Archive for Image of the day - page 7

Conducting of qualification and acceptance tests is one of our core competencies. Due to popular demand, we are also offering it as a service for our partners and customers. If you are a space #startup without own infrastructure yet or an established player in urgent need, reach…

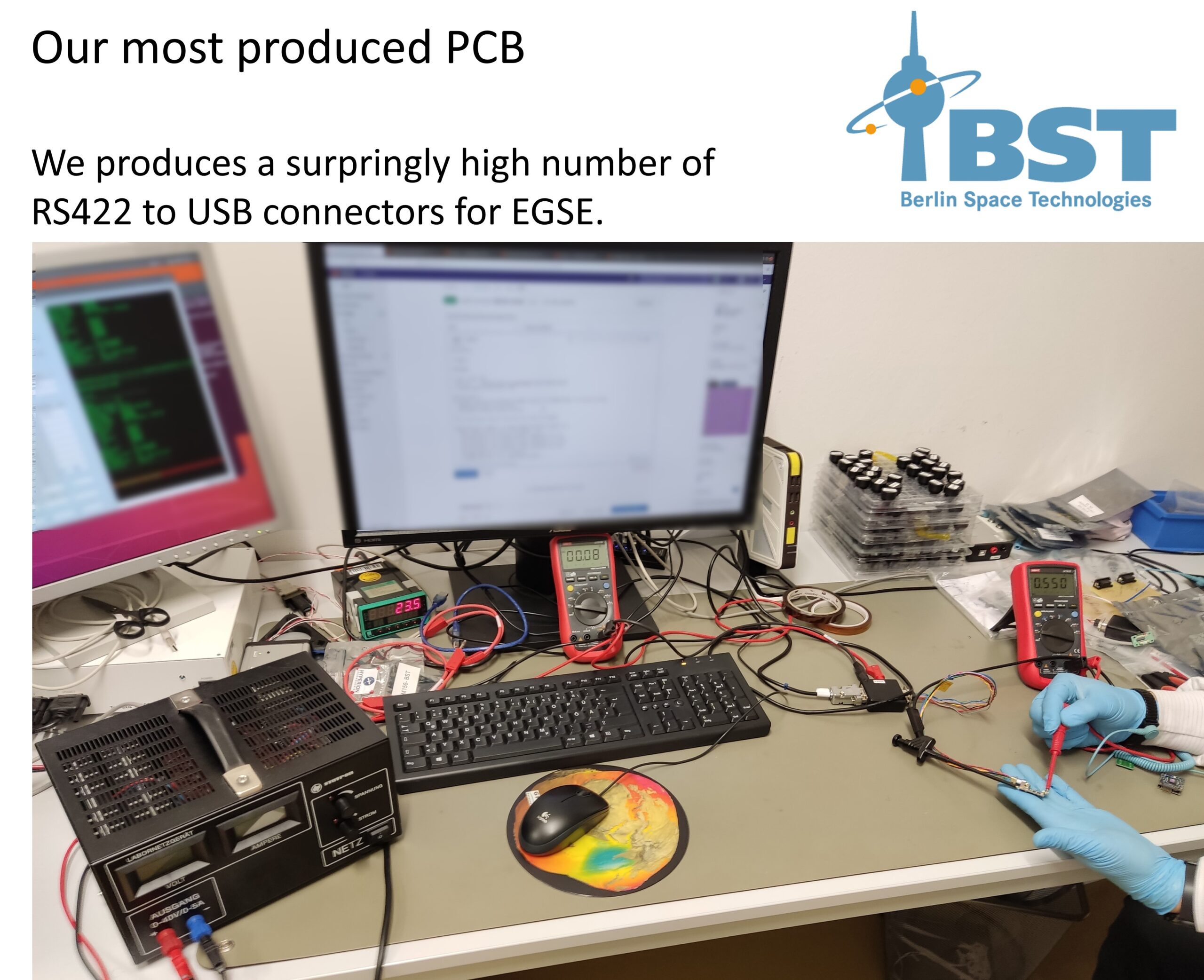

We have made the choice to make the life of our customers easier: this means that stand alone connectors and software for incoming inspection is included with each unit. As a result, the in-house produced RS422->USB connectors are the single most produced PCB at BST….

Sometimes it’s the simple things that make a difference. All BST satellites have covers for their delicate parts. This can be as simple as a Mylar Foil covering a star tracker or in this case a metal sheet to cover the solar panels. #newspace #smallsatellites #qualityassurance #berlinstartups

When building satellites, one learns to appreciate small things. Here you can see the in-house manufacturing of miniature shock dampers that prevent damaging of delicate things during the rocket launch. #newspace #smallsatellites #berlinstartups

Aside from star trackers our reaction wheels are our second most sold product. Here you can see a wheel during assembly. The RWA05 from Berlin Space Technologies GmbH is a space proven reaction wheel for 50-100kg satellites. It offers 0.5Nms storage and 14mNm torque. One of the…

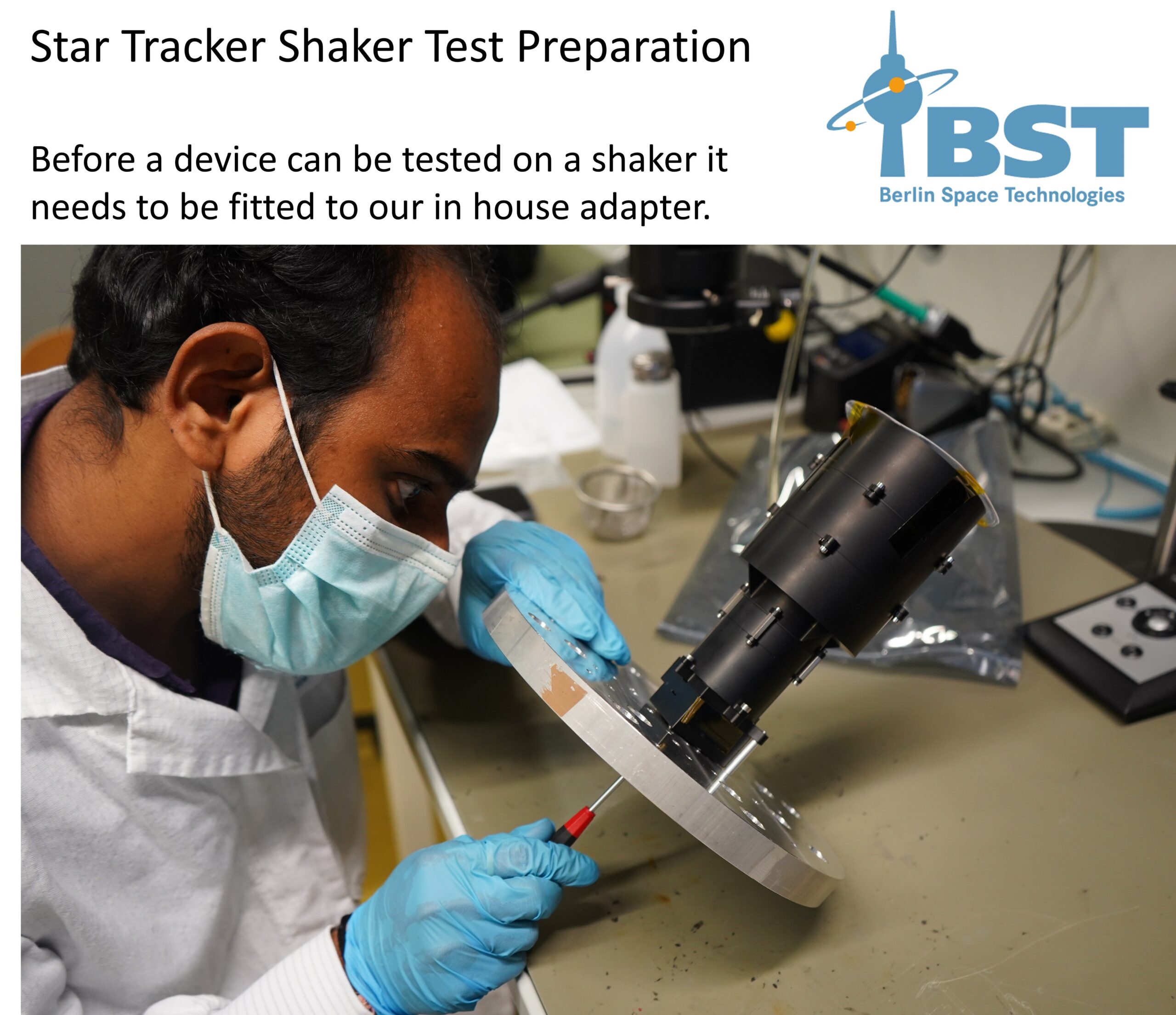

All our flight hardware undergoes mechanical qualification before delivery. Here you can see one of our star trackers being prepared for a shaker test. The picture shows the fit test of a ST200 star tracker with extended baffle onto one of our adapters, which we…

Contamination of optical surfaces is a real problem of any space mission. You can’t really send over something with a wipe. Therefore, we make sure that everything is and remains clean. The image shows a picture of one of the 50MPx detectors that we use…

While our mechanical parts are produced externally, it always is handy to have a fully equipped mechanical workshop to do minor modifications. It greatly adds to speediness of implementation during the prototype phase. #newspace #smallsatellites #mechanicalengineering #berlinstartups

Thank you Federation of German Security and Defence Industries e.V. and AFCEA Bonn for inviting us to participate in the 4th Convent for digital convergence of security and defence industry.